Discover new opportunities to overcome costs & improve performance

Why factories are choosing NBR Newitsystems for monitoring and diagnosis of their industrial assets?

Energy Efficiency

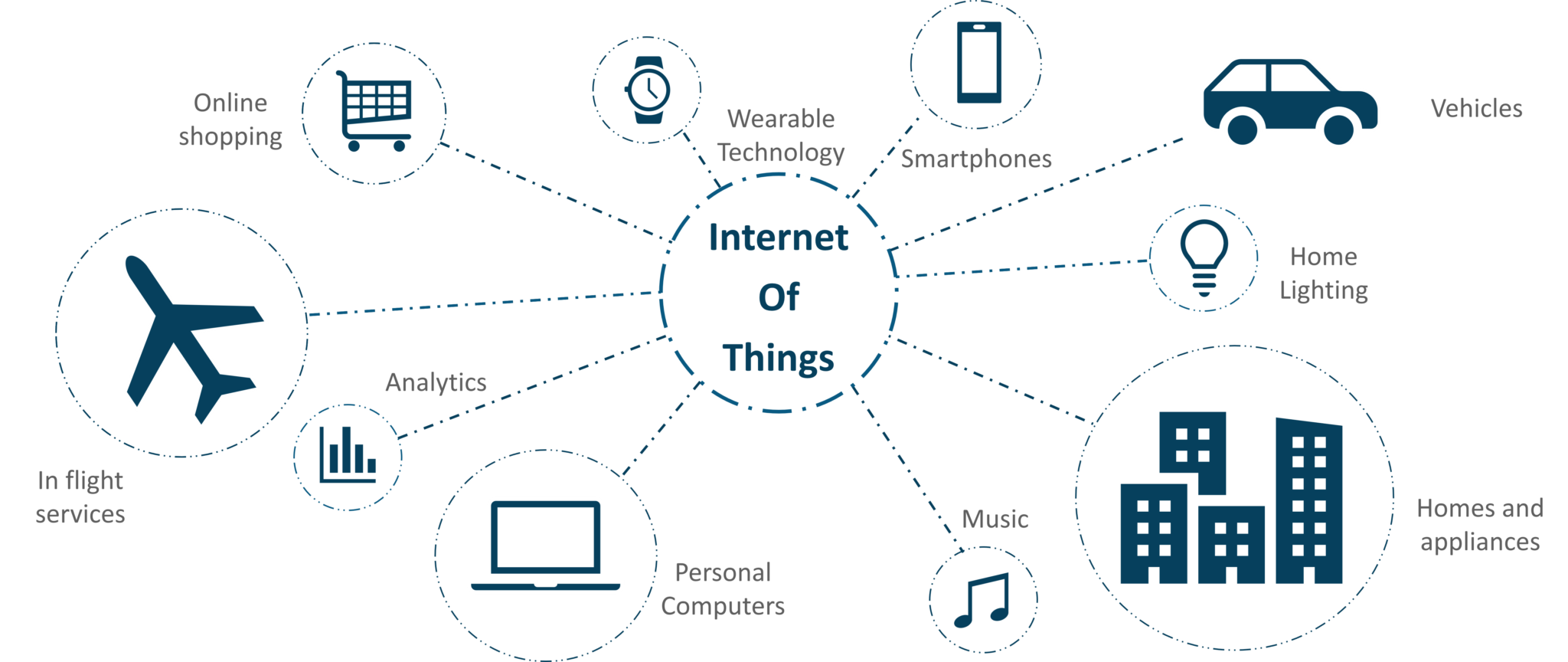

Every device in a factory will have different times and requirements that they may be active, some work almost every second while others only work every now and then resulting in a large amount of downtime or wasted energy, being able to track energy efficiency is one of NEWITsystemscapabilities

Waste Reduction

Waste is one of the biggest drawbacks in a large factory and can severely hinder performance as well as income. Optimising energy, quantity and timing with the machinery will reduce waste drastically, NEWITsystems is capable of this optimisation.

Predictive Maintenance

NEWITsystems is able to monitor machines at all times in real time and therefore is able to detect any anomalies that occur and potential maintenance requirements to prevent any damage or problems that could arise before they happen.

OEE Optimisation

NEWITsystems again is constantly collecting critical data and allows you to interpret and examine data to collect important information such as Profit and production tracking, KPI tracking and detecting the health of each device.

More Predictive Financial Target

Being able to monitor profitability is also very important in a factory, NEWITsystems has the ability to set goals with budgets and finance, depending on the goals set, it will detect if the factory is up to standard or performing below average.

Less Down Time

Down-time is always aimed to be kept to an absolute minimum to optimise factory performance. This section essentially summarises the final effects of all the different features.

Production and tracking profits

Our system provides an overview of all companies at an enterprise level and visualizes the performances of each company, enabling management to assess the current status such as spare availability or delays in the supply chain and take frequent actions if necessary. The KpIs are customized to your needs and are tracked in real time against the set targets.

Our Locations.

Contacts

Address:

Head office

Level 10

34 Shortland St,

Auckland, 1010, NZ